When seeking a cost-effective rubber material with excellent resistance to weather, heat, and environmental factors, EPDM grommets, gaskets, tubing, and other components are an ideal solution.

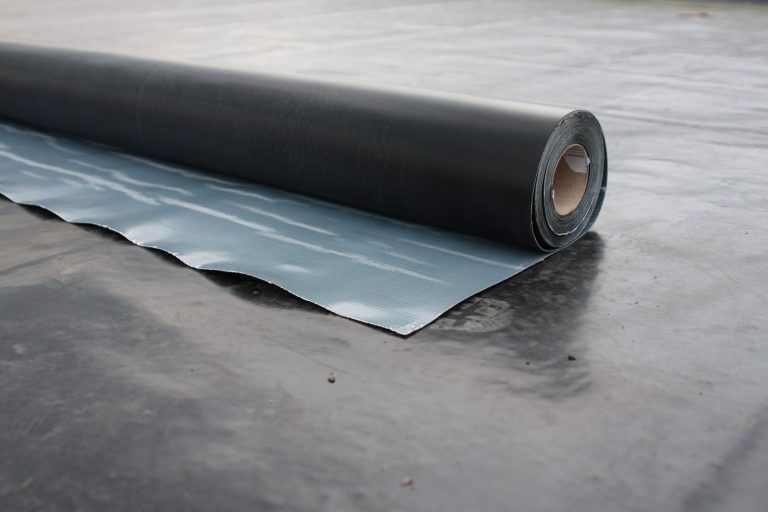

EPDM, or ethylene propylene diene monomer, is a highly versatile rubber commonly used across various industries, including automotive and HVAC systems. It serves as a budget-friendly alternative to silicone, offering durability and the ability to withstand harsh weather conditions, abrasion, and other challenges over extended periods with proper maintenance.

Thanks to its physical resilience, performance reliability, and affordability, custom EPDM parts can help reduce costs and improve efficiency in diverse applications. These advantages have made EPDM a preferred material for many essential components.

What Does EPDM Rubber Come From?

EPDM, a synthetic rubber, is produced through the polymerization of ethylene, propylene, and specific alpha-olefin comonomers. Its origins trace back to Nobel Prize laureate Karl Ziegler, a German scientist who discovered its strong and flexible properties during polymerization experiments.

Introduced to the U.S. market in the early 1960s, EPDM quickly gained traction in industries like roofing due to its cost-effectiveness and favorable properties. It became notable as the first elastomer to combine heat resistance, ozone resistance, mechanical strength across a wide temperature range, and chemical stability.

While materials have since been developed for specialized high-temperature or extreme-performance needs, EPDM remains a popular choice for many applications, balancing durability, performance, and affordability.

EPDM Rubber Properties

- Common Name: EPDM

- ASTM D-2000 Classification: CA

- Chemical Definition: Ethylene Propylene Diene Monomer

- Temperature Range

- Low Temperature Usage:-20° to -60° F | -29⁰C to -51⁰C

- High Temperature Usage: Up to 350° F | Up to 177⁰C

- Tensile Strength

- Tensile Range: 500-2500 P.S.I.

- Elongation: 600% Maximum

- Durometer (Hardness) – Range: 30-90 Shore A

- Resistances

- Aging Weather – Sunlight: Excellent

- Abrasion Resistance: Good

- Tear Resistance: Fair

- Solvent Resistance: Poor

- Oil Resistance: Poor

- General Characteristics

- Adhesion to Metals: Fair to Good

- Solvent Resistance: Poor

- Compression Set: Good

EPDM Rubber Applications

HVAC

- Compressor grommets

- Mandrel formed drain tubes

- Pressure switch tubing

- Panel gaskets and seals

Automotive

- Weather stripping and seals

- Wire and cable harnesses

- Window spacers

- Hydraulic brake systems

- Door, window, and trunk seals

Industrial

- Water system O-rings and hoses

- Tubing

- Grommets

- Belts

- Electrical insulation and stinger covers

Interested in EPDM Rubber and its Products?

Call +91 70696 80580 or complete our online form to request a quote.

Not sure which material you need for your custom rubber product? You are just a click away Contact Us.